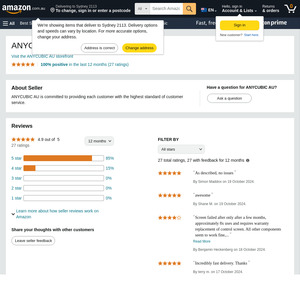

This is a lightning deal so you need to be quick. In order to get this price, you need to tick the $100 off Coupon on the 3D Printer and add to cart.

https://www.amazon.com.au/gp/product/B08HH329TR

Then add the 1KG Resin to cart.

https://www.amazon.com.au/dp/B07YZ7F55V

Both need to be purchased in the same order. Price will be $120 at checkout

CamelCamelCamel

CamelCamelCamel

Missed out !

Changed screen to click the resin code - already up to $320 - $100 = $220

Doh!

Still a great price @ $220